Modular Furniture Design: Tool-Free & Swappable Assembly

Summary

This project began with Plate A, a panel material made from recycled PET flakes sourced from used cosmetic containers.

While designing a stool with this material, attention shifted to its potential beyond a single product. CNC-cut panel

furniture is already common, so the focus became how to make this approach more distinctive. Considering the high cost

of Plate A, using it selectively was explored—leading to the idea of swappable parts using different materials. This

naturally led to modularity, which offered benefits such as reduced volume, easier transport, and greater adaptability.

The concept evolved from this progression of ideas.

In the process of planning and realizing spatial designs, we use a wide variety of chairs and stools.

Although we strive to reuse as many as possible after pop-ups or exhibitions to reduce unnecessary resource consumption, in reality, we often need to purchase new pieces to match each space’s unique concept.

Individually, these items may not seem bulky, but many are difficult to stack, and the large total quantity means that storage for reuse consumes a considerable amount of space.

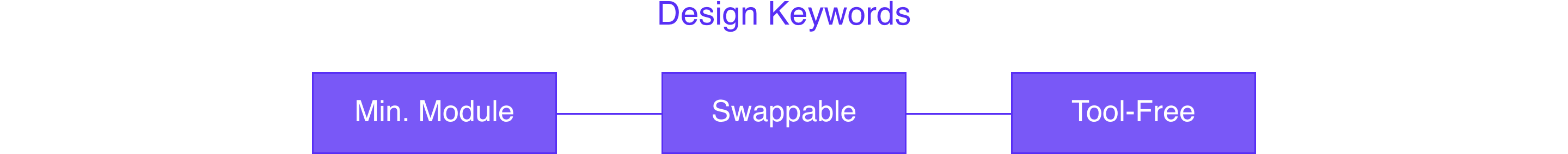

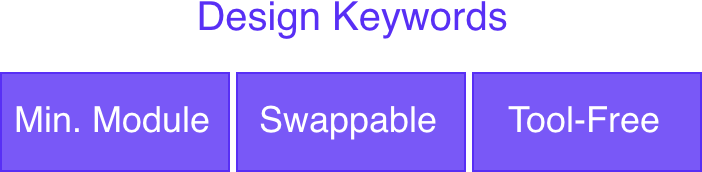

We established three core design directions—each with its own meaning, yet interconnected in principle.

Minimize the number of modules to reduce production variations, which allows for greater material versatility and enables compact stacking for space efficiency.

Simplify structure and assembly, designing a system that requires no screws, nails, or tools, so that anyone can assemble, disassemble, or modify it easily in any location.

Balance form and function, ensuring that the structure remains both aesthetically coherent and functionally flexible across various space types.

Phase.0

Flat Base

Flat Base

Phase.1

Slotted

Slotted

Phase.2

Tabbed

Tabbed

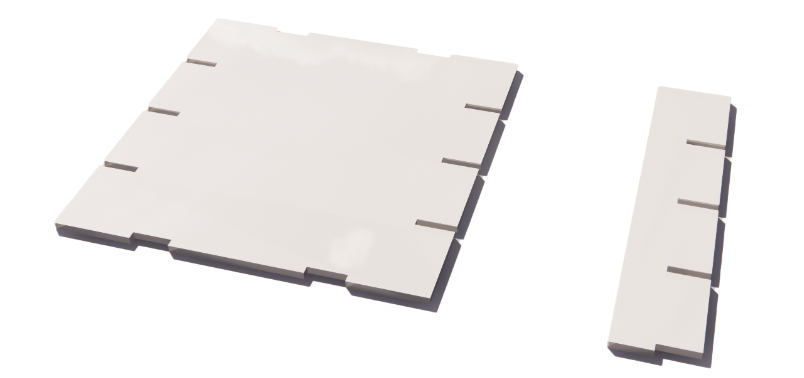

When using a single module type—similar to waffle blocks—we found that continuous overlapping of wide surfaces resulted in excessive density.

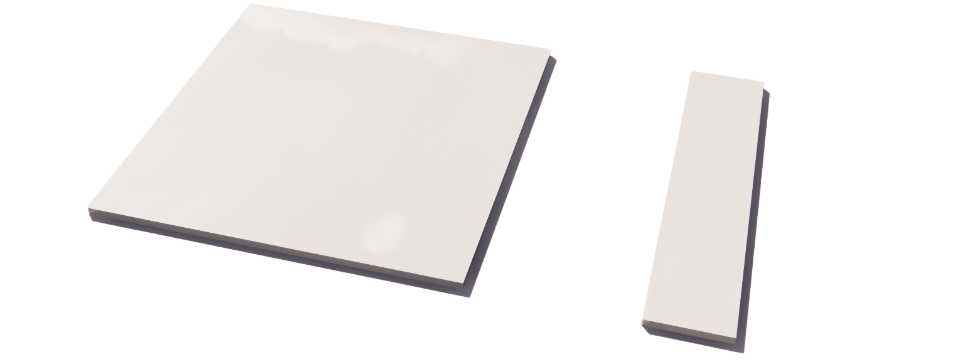

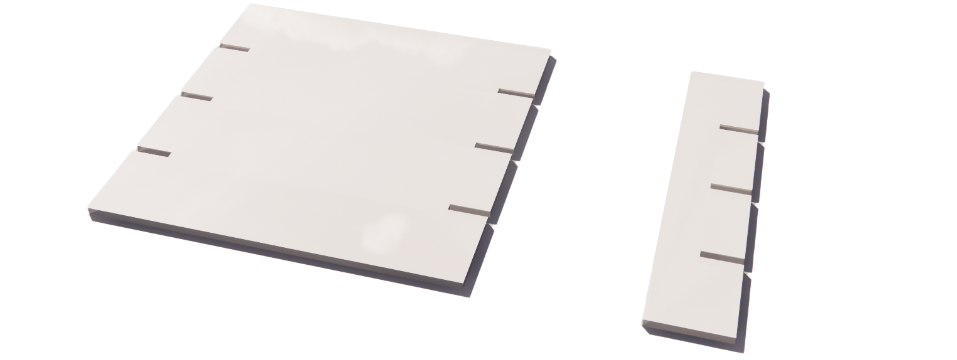

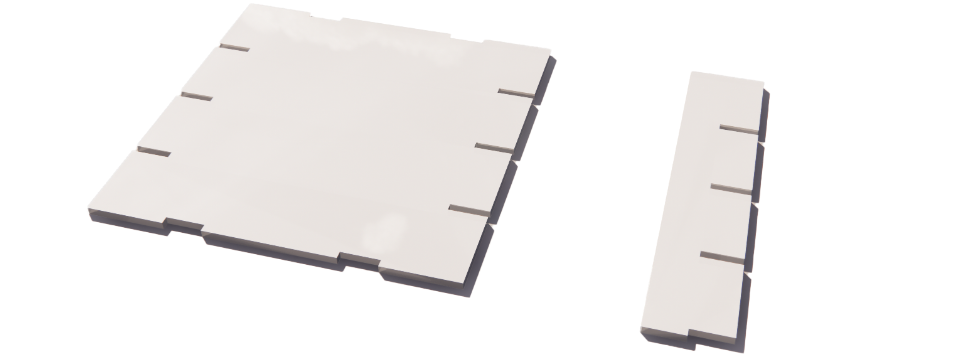

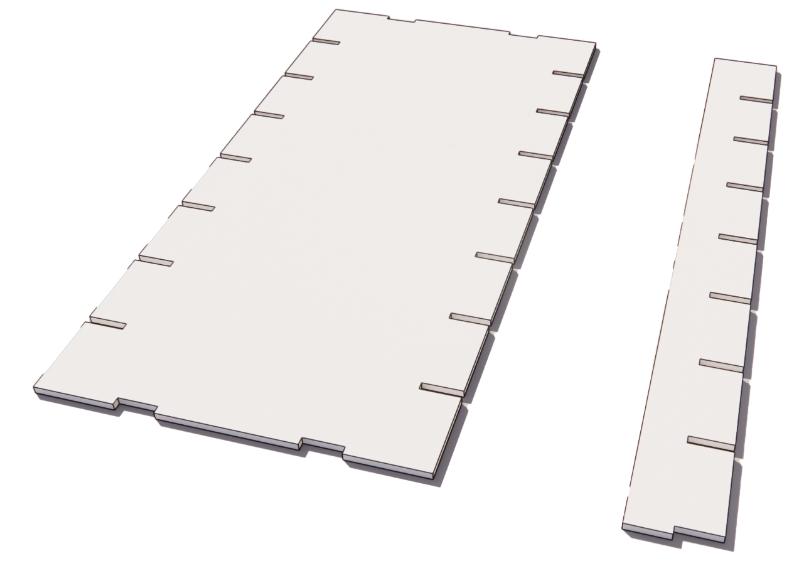

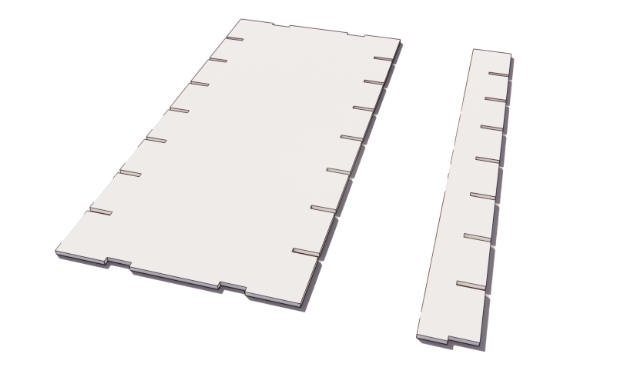

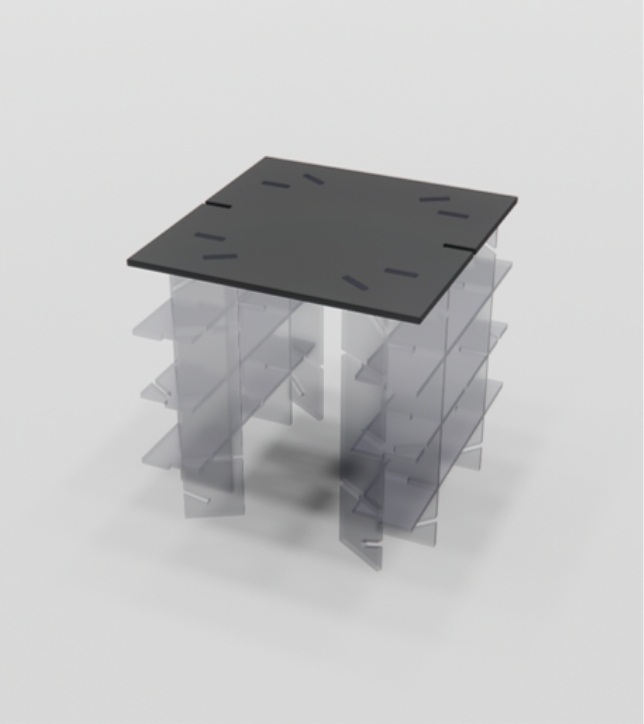

To address this, we established a modular system consisting of: Square plates serving as surface elements, and Rectangular plates serving as linear or structural elements.

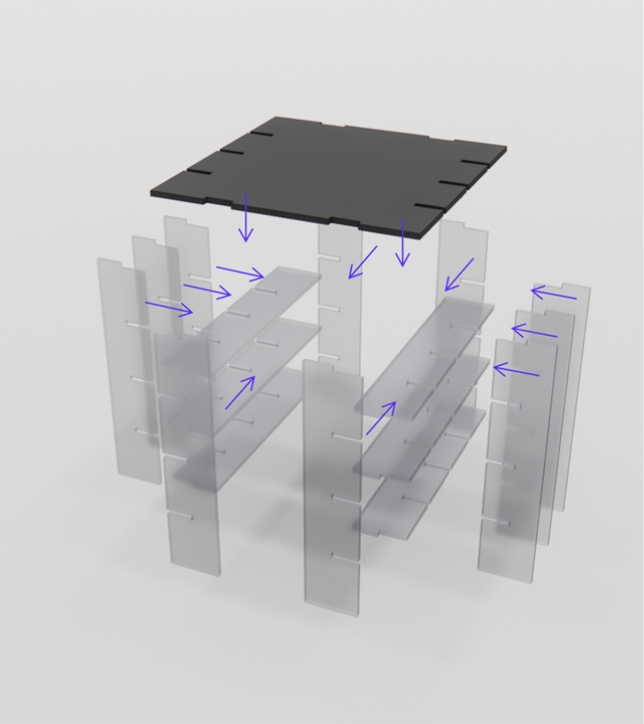

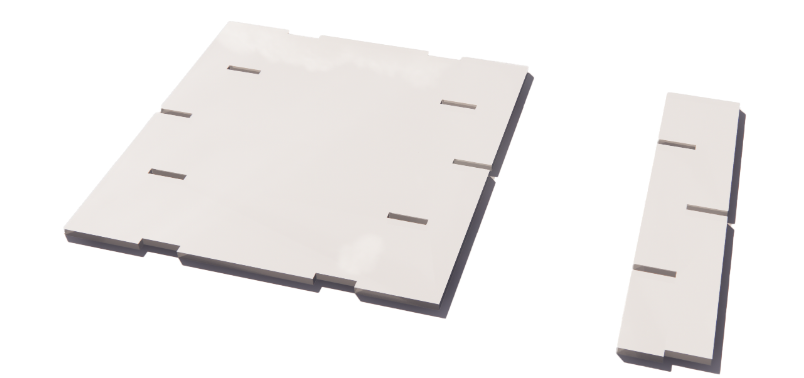

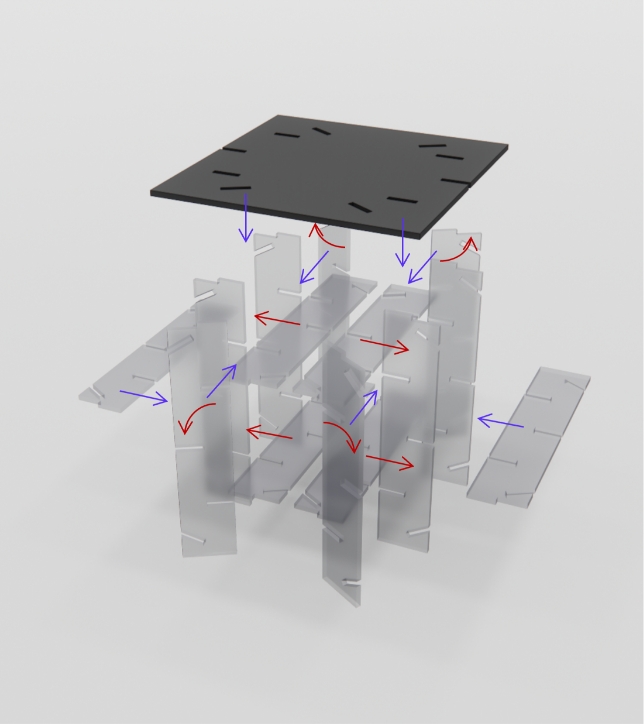

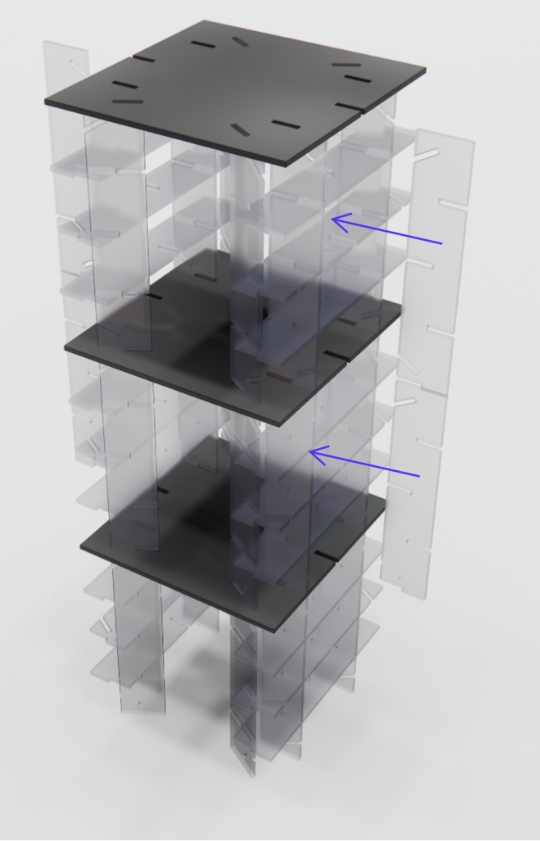

In Step 1, we designed slots that allow modules to interlock securely. In Step 2, we added protruding joints that enable intuitive insertion and connection.

Phase.3

Extension

Extension

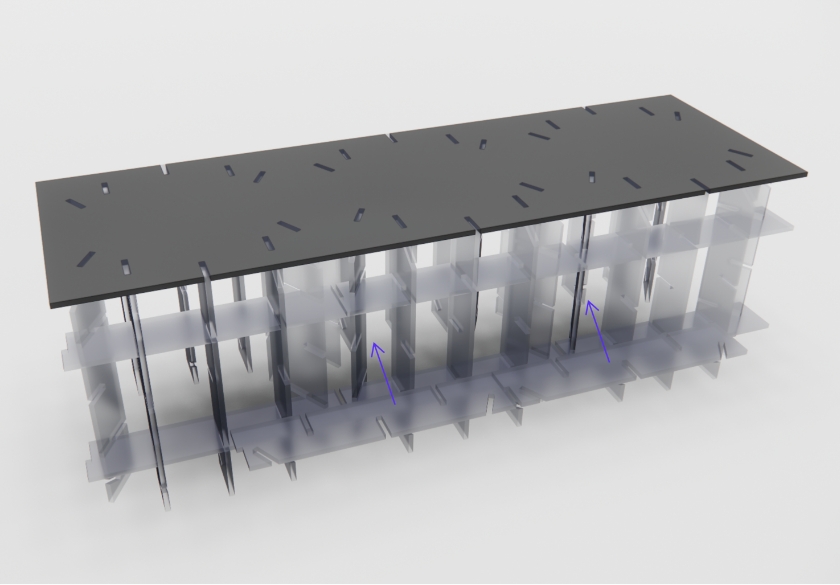

Next, we introduced an expanded module, doubling the size of the original unit to explore broader compositional possibilities.

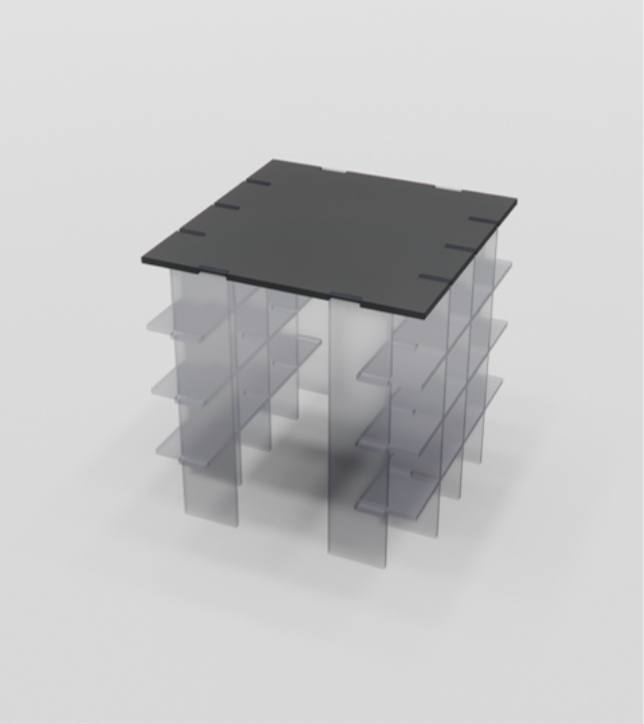

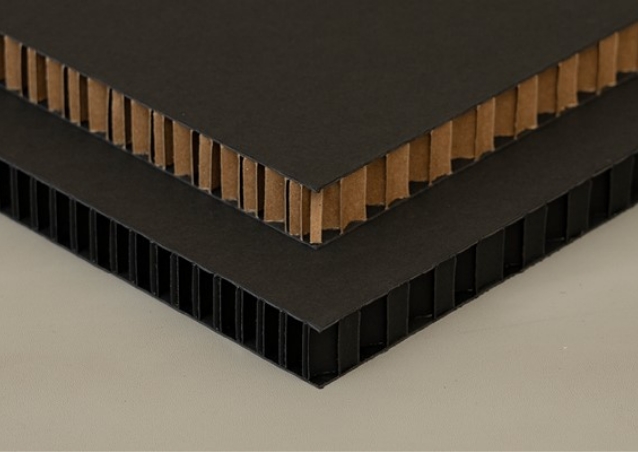

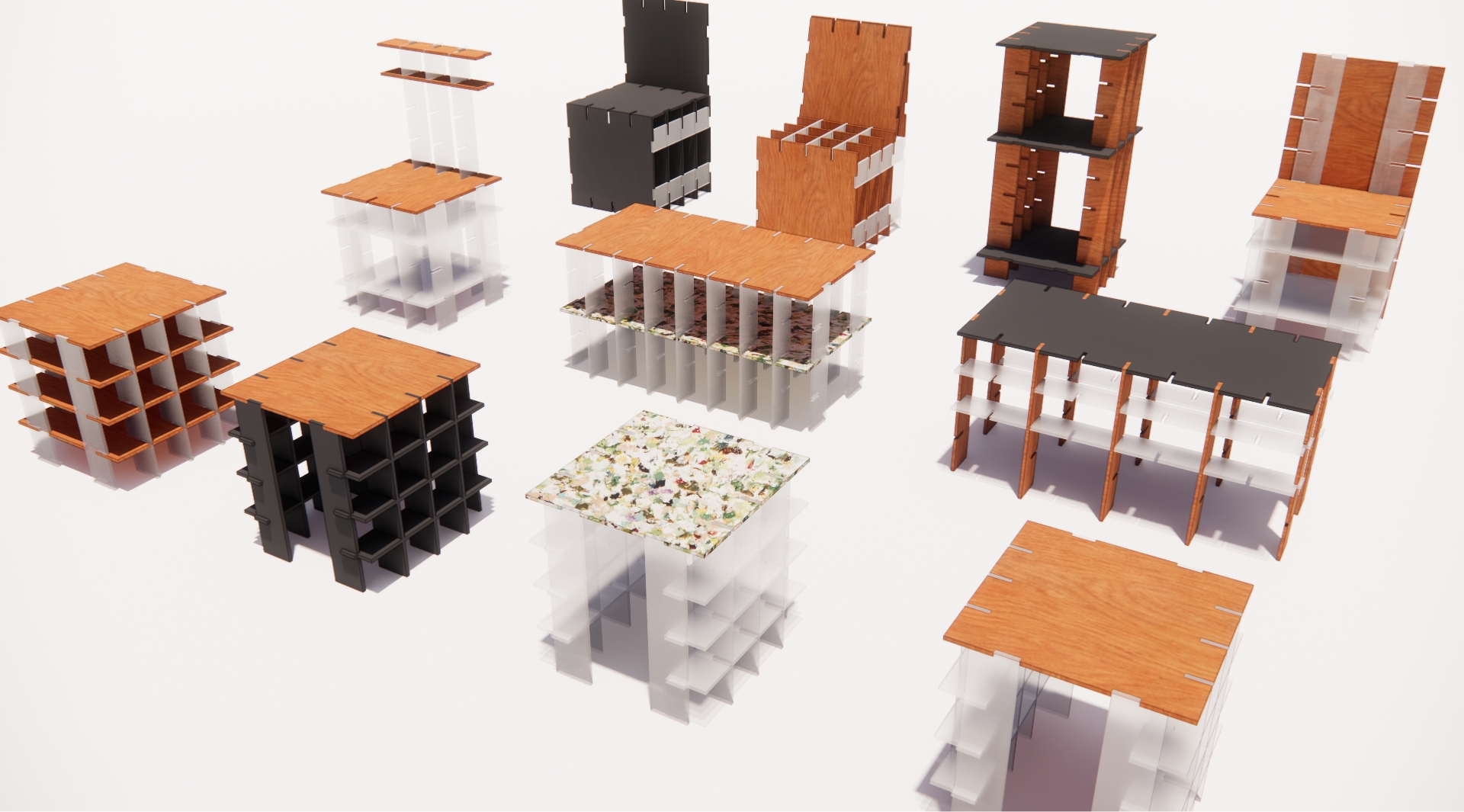

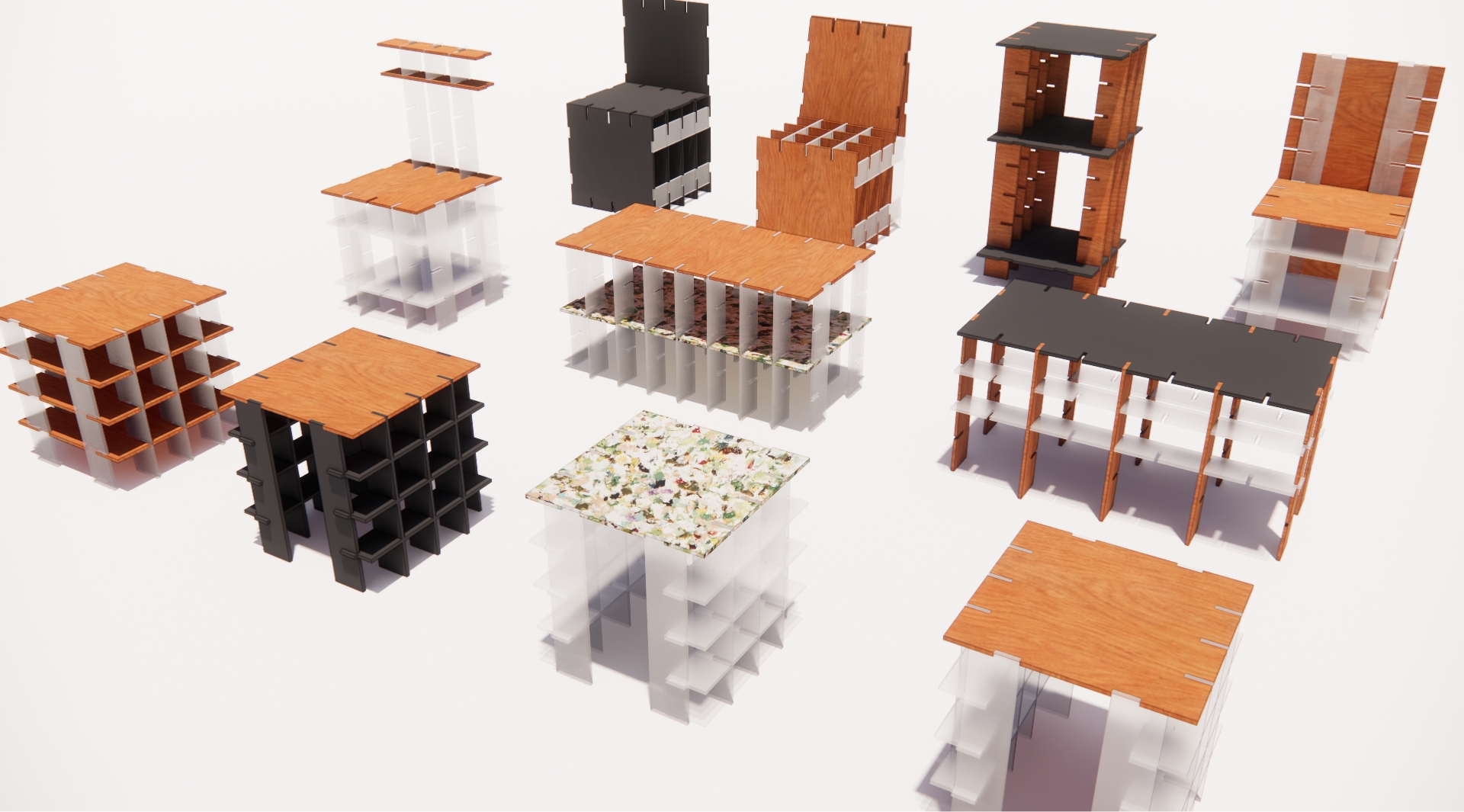

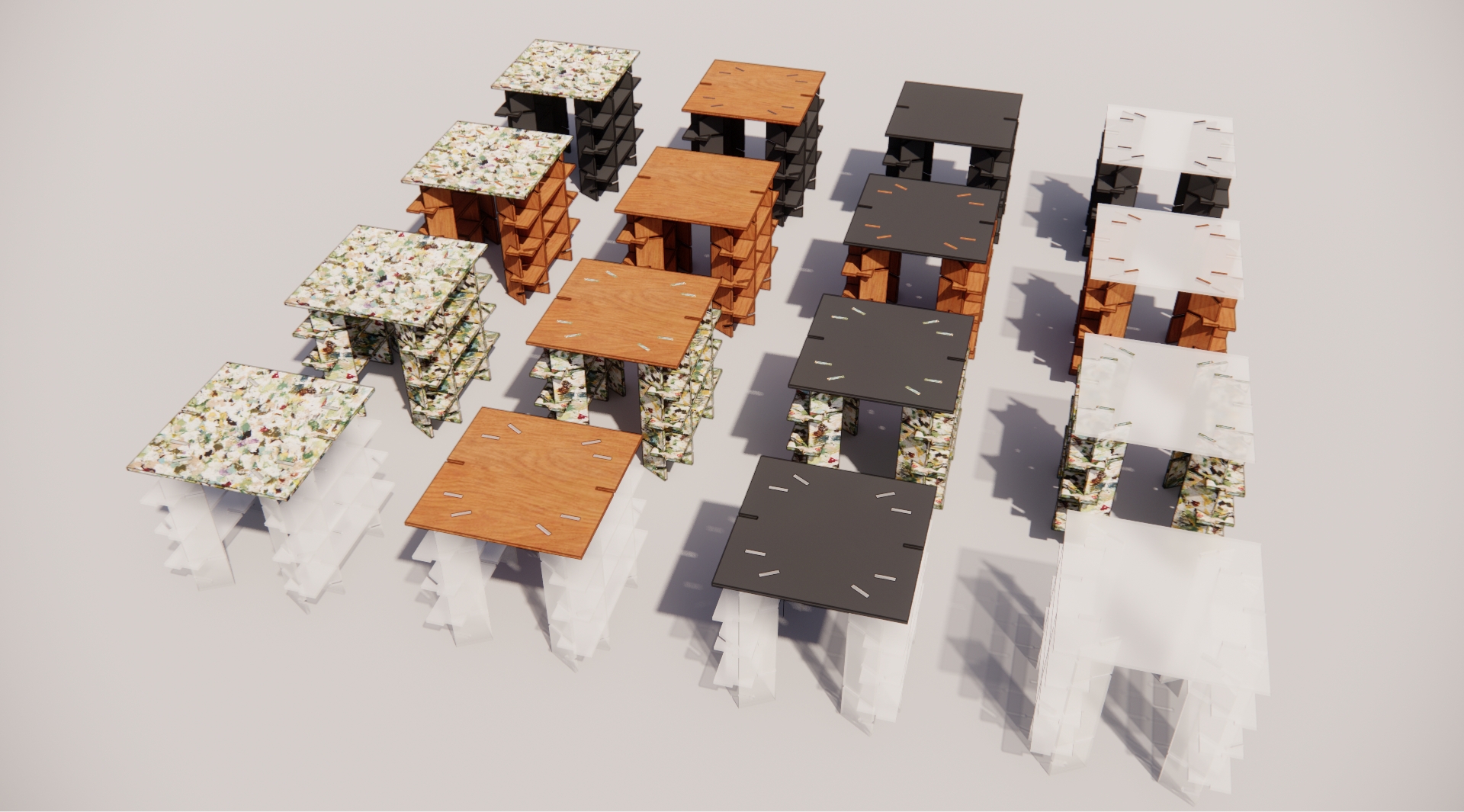

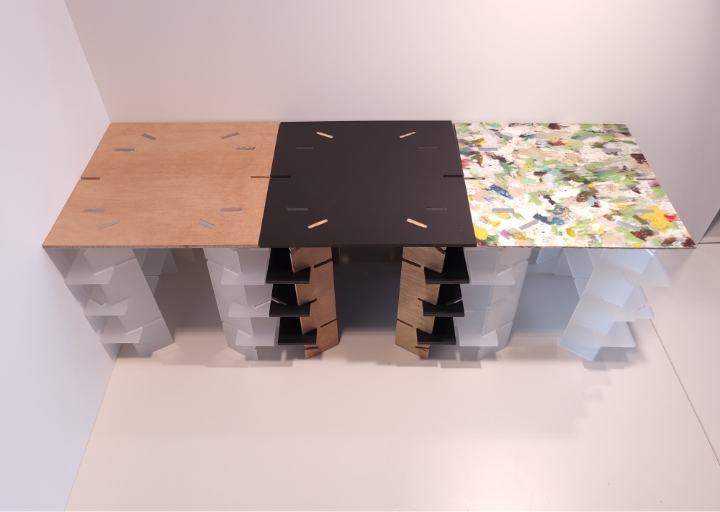

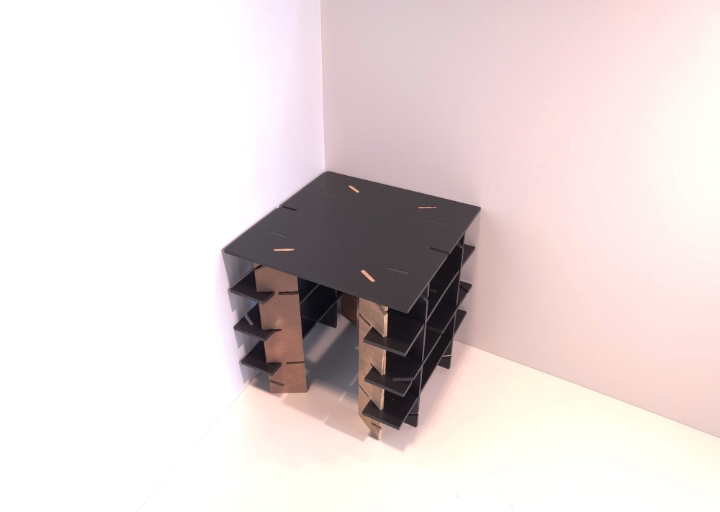

For material experimentation, we selected frosted acrylic as the primary material and combined it with paper, plastic, and wood. Specifically, we simulated various assembly configurations using black honeycomb board for paper, Plate A for plastic, and solid wood panels for wooden applications.

For material experimentation, we selected frosted acrylic as the primary material and combined it with paper, plastic, and wood. Specifically, we simulated various assembly configurations using black honeycomb board for paper, Plate A for plastic, and solid wood panels for wooden applications.

Next, we introduced an expanded module, doubling the size of the original unit to explore broader compositional possibilities.

For material experimentation, we selected frosted acrylic as the primary material and combined it with paper, plastic, and wood.

Specifically, we simulated various assembly configurations using black honeycomb board for paper, Plate A for plastic, and solid wood panels for wooden applications.

During actual sample production, we found that durability was significantly insufficient.

While injection molding, as used in waffle blocks, ensures dimensional accuracy, cutting tolerances and material thickness variations led to loose interlocking joints.

Additional issues included: Structural members only interlocking in one direction, and The top panel failing to stabilize the overall framework.

To resolve these, we returned to Step 2 and implemented several refinements:

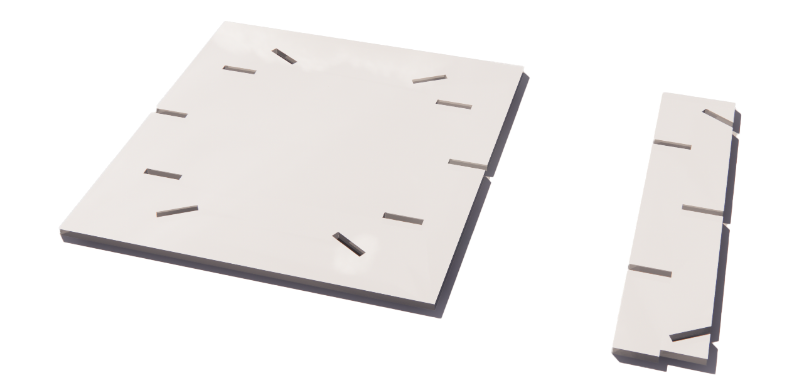

1, Added zigzag slots to the structural members, allowing bidirectional assembly.

2, Introduced diagonal rotation slots for the top panel to provide stronger fixation and subtle visual variation.

Phase.2

Tabbed

Tabbed

Phase.3

Closs Lock

Closs Lock

Phase.4

Tilt Lock

Tilt Lock

A wide range of combinations can be achieved depending on the materials applied to the top panel and structural components.

A wide range of combinations can be achieved depending on the materials applied to the top panel and structural components.

The interlocking structural members between two stools enable horizontal expansion of the module, while alternating the top panel slots—either from above or below—allows for vertical stacking and extension.

The interlocking structural members between two stools enable horizontal expansion of the module, while alternating the top panel slots—either from above or below—allows for vertical stacking and extension.

The interlocking structural members between two stools enable horizontal expansion of the module,

while alternating the top panel slots—either from above or below—allows for vertical stacking and extension.

We virtually arranged modular stools made from different materials in spaces with distinct design concepts,

demonstrating how the same structural logic can adapt seamlessly to diverse spatial identities.

demonstrating how the same structural logic can adapt seamlessly to diverse spatial identities.

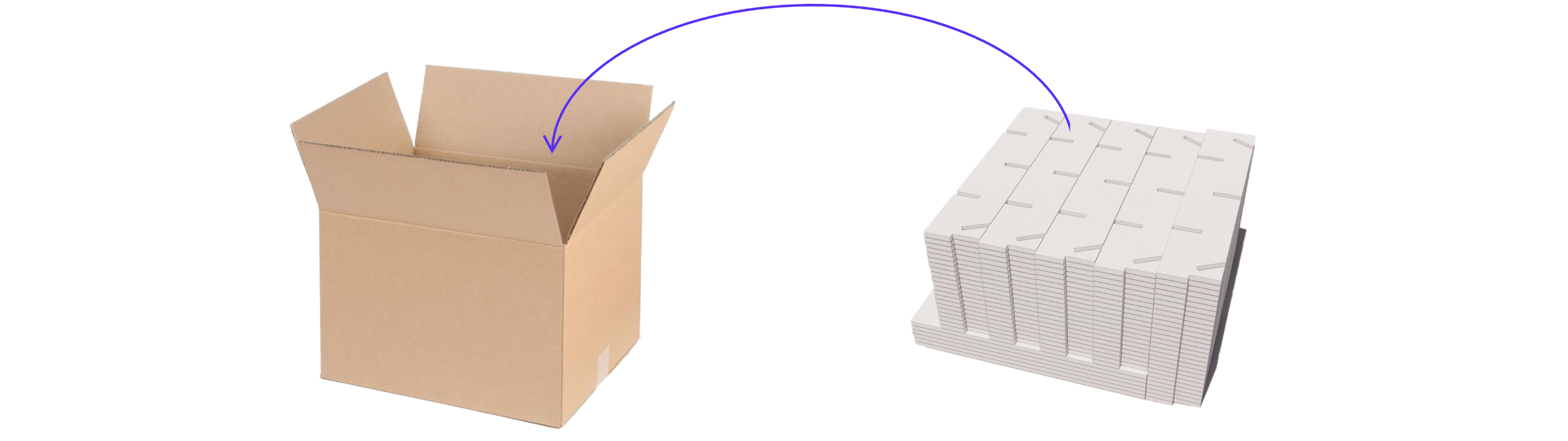

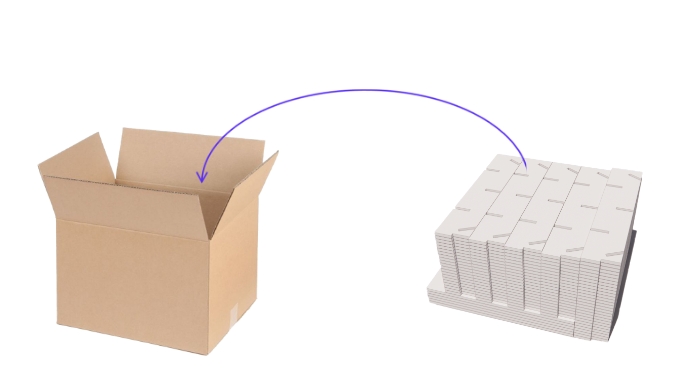

A standard moving box can typically hold only one stool.

However, by disassembling the modular components, the same box can accommodate

up to six sets of modules, dramatically improving storage and transport efficiency.

However, by disassembling the modular components, the same box can accommodate

up to six sets of modules, dramatically improving storage and transport efficiency.

Min. Module / Swappable / Tool-Free

Through this furniture production module proposal—anchored in the three core keywords of modularity,

flexibility, and sustainability — we aim to inspire new ideas for sustainable furniture utilization:

designs that can be easily stored and transported, yet adapt and be reused across diverse spatial concepts.

flexibility, and sustainability — we aim to inspire new ideas for sustainable furniture utilization:

designs that can be easily stored and transported, yet adapt and be reused across diverse spatial concepts.

- Amorepacific Creatives

- Design

- Hyun Younghun